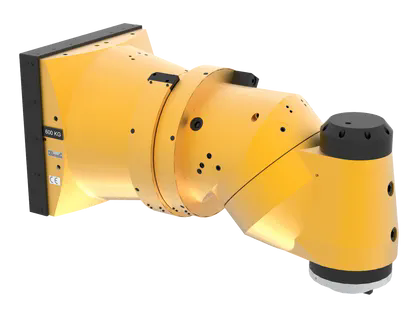

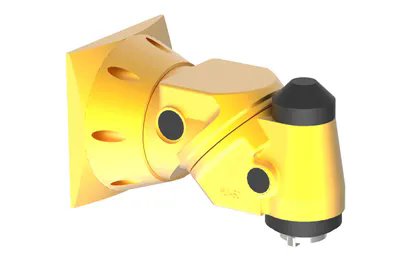

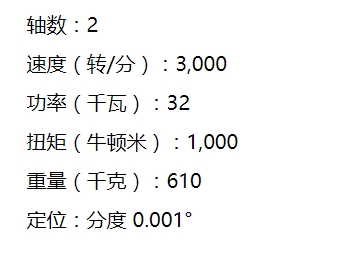

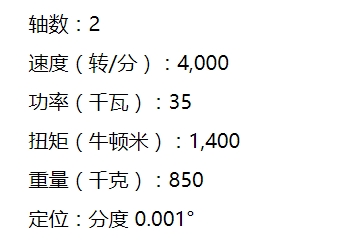

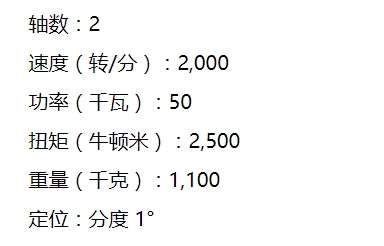

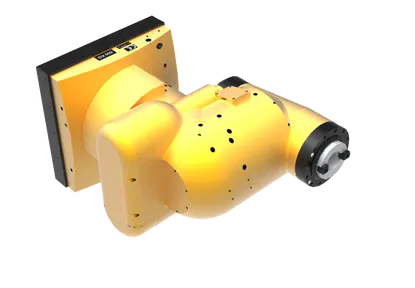

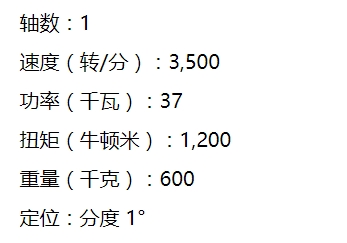

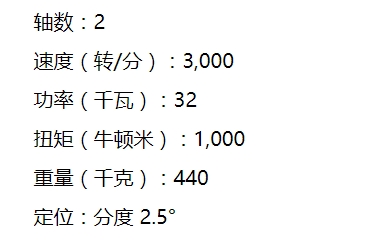

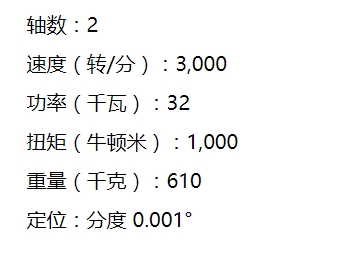

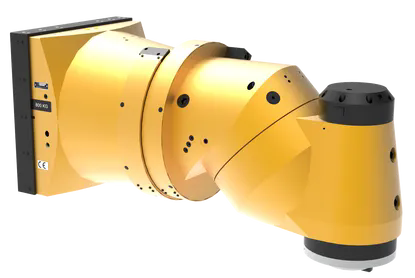

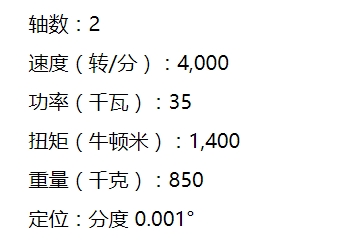

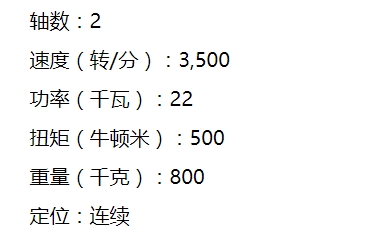

HUIL 50

The universal automatic indexing HUIL 50 milling head shares the same design philosophy as the HUI 50 milling head. However, it offers more precise positioning and significantly improved rotational speed. The head is equipped with cooling channels to ensure uniform cooling.

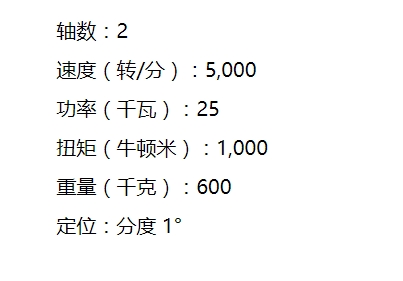

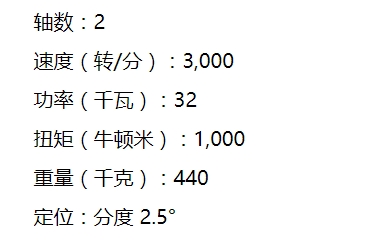

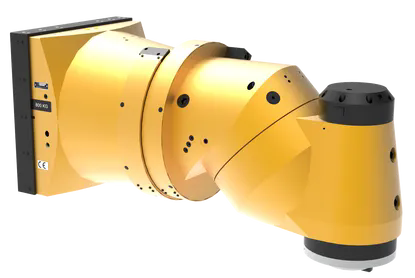

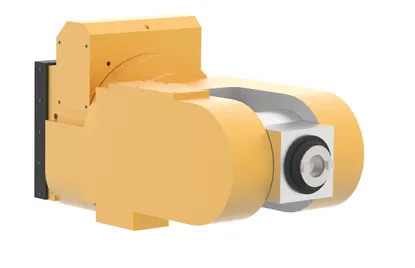

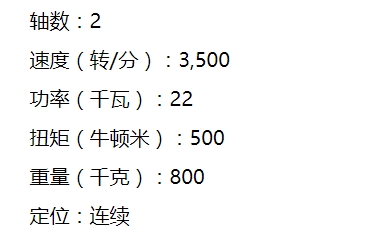

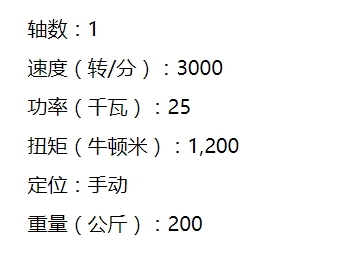

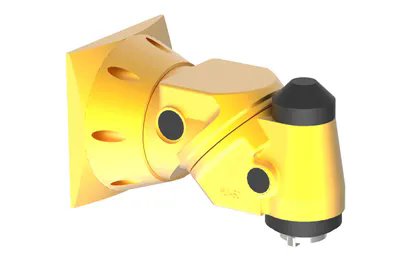

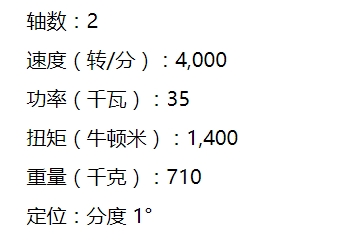

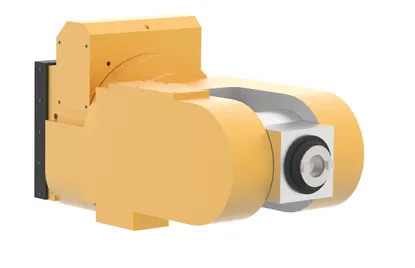

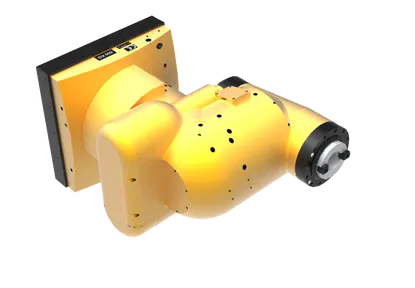

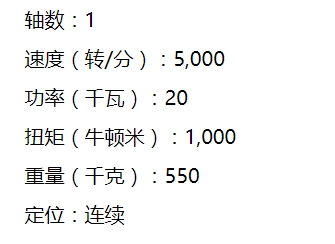

HUI 50

The HUI 50 milling head automatically indexes at 2.5° on two planes, thus increasing efficiency when rotating the milling head spindle relative to the machine's orthogonal coordinate system.

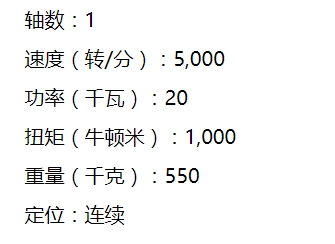

HUF 50

The universal continuous positioning HUF 50 milling head consists of three compact, interconnected basic components that can rotate relative to each other. The positioning of the components is adjusted by the rotation of the machine's main spindle. Continuous positioning is ensured by a servo motor, which enables rotation of the Hirth tooth slot and achieves a step of 0.001° on the A-axis and C-axis.

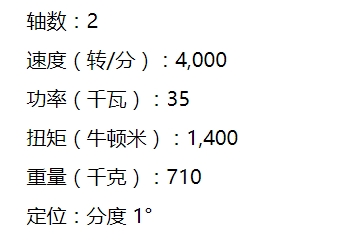

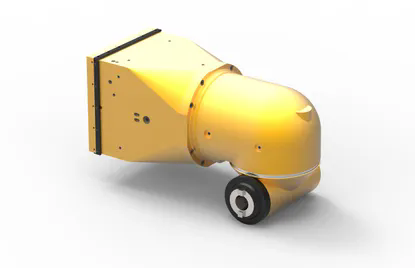

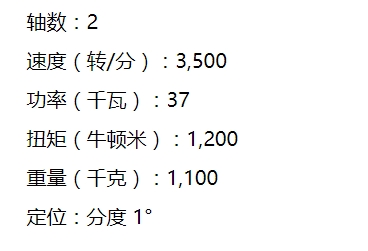

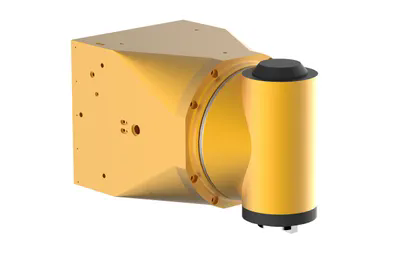

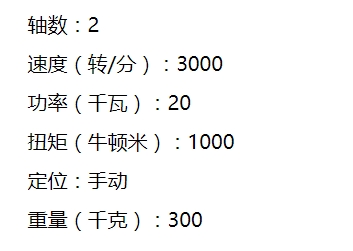

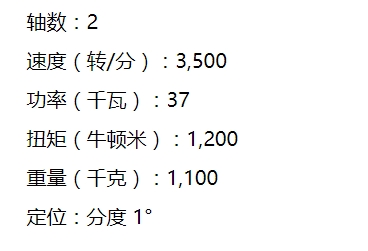

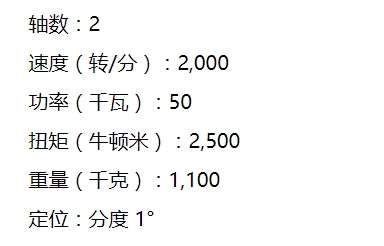

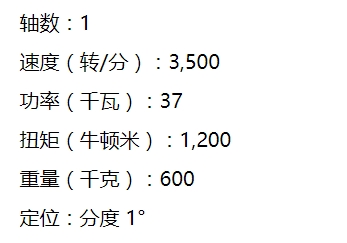

HUIT 50

The universal automatic indexing HUIT 50 milling head shares the same design philosophy as the HUIL 50 milling head. However, this head has greater power and higher torque.

HUFT 50

The universal continuous positioning milling head HUFT 50 shares the same design philosophy as the HUF 50 milling head. However, this head has greater power and higher torque. It is equipped with cooling channels for uniform cooling.

HOI 50

The orthogonal automatic indexing HOI 50 milling head consists of three basic interconnected components that can rotate on the A-axis and C-axis, achieving overall positioning of the milling head spindle. The positioning of the rotating components is ensured by the mechanical transmission of the machine's main spindle, allowing for 180° positioning on the C-axis and 180° on the A-axis.

HOIL 50

The orthogonal automatic indexing HOIL 50 milling head shares the same design philosophy as the HOI 50 milling head. However, this head is significantly lighter, with a weight reduction of more than half.

HOIT 50

The orthogonal automatic indexing HOIT 50 milling head shares the same design philosophy as the HOI 50 milling head. However, this head has greater power and higher torque. It is specifically designed for hydrostatic machine tools.

HV/V

The milling head consists of three compact, interconnected basic components that can rotate relative to each other on the A-axis and C-axis. The relative movement of these components is ensured by separate servo drives, which allow for continuous positioning throughout the entire rotation range and continuous movement of both axes during machining.

HPFL 50

The milling head consists of three compact, interconnected basic components, two of which are rigidly connected, and one component can rotate on the A-axis. This movement is achieved by an independent servo drive, allowing for continuous control throughout the entire rotation range and smooth movement of the A-axis during machining.

HPI 50

The milling head consists of two compact, interconnected basic components that can rotate relative to each other to achieve the necessary positioning of the milling head spindle. The positioning of the rotating components is ensured by the mechanical transmission of the machine's main spindle, allowing for ±185° positioning.

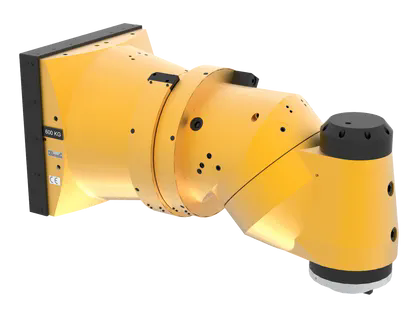

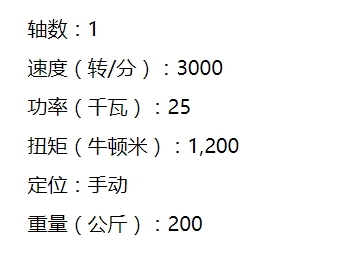

HPR 50

The manual right-angle milling head HPR 50 consists of two compact, interconnected basic components that can rotate relative to each other to achieve the required position of the milling head spindle. The adjustment angle increments are 0.1° and can be displayed on a graduated scale equipped with a cursor.

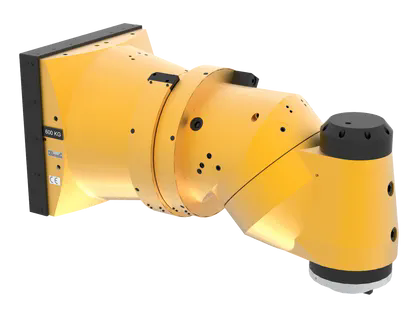

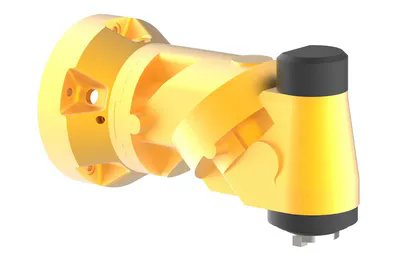

HUR 50

The universal manual positioning milling head HUR 50 consists of three compact, interconnected basic components that can rotate relative to each other, thus achieving the overall position required for the milling head spindle. The adjustment angle can be read in increments of 0.1° on a graduated scale equipped with a cursor. The head can be set to 8 basic positions (4x90° on the vertical connection surface and 2x180° on the oblique indexing surface—using positioning pins).

UFP-40/50

Used as an accessory for WH 10 and WHN 13 machine tools. Suitable for machining surfaces at various angles parallel to the machine's main spindle. The tool and milling head device are manually clamped onto the machine.

Dian Public Security Registration No. 53080202000194

Dian Public Security Registration No. 53080202000194